ORTHODESIGNS, based in Limassol, Cyprus, is an innovative company specialising in 3D printing to manufacture prosthetic and orthotic devices. Savvas Savva and Kyriakos Efstathiou, both founders, are dedicated to developing high-quality, individualised healthcare solutions. ORTHODESIGNS ensures that its products meet both functional and aesthetic demands, helping the patient achieve better comfort around their prosthetics and orthotics and great mobility.

Savvas Savva (left) and Kyriakos Efstathiou (right)

Savvas Savva (left) and Kyriakos Efstathiou (right)

The Challenge before LutraCAD

Before integrating LutraCAD in their production workflow, ORTHODESIGNS faced several challenges. Their insole design was a manual process, relying on traditional CAD tools that required multiple, iterative steps to ensure proper fit and functionality.

This time-consuming process often took 20 to 30 minutes per insole, which became unsustainable as their demand grew. Additionally, consistency in the designs sometimes resulted in material waste and costly reworks. Their previous methods' slow and labour-intensive nature restricted their ability to scale, limiting output and increasing production costs.

The Transformation

The design software provided by LutraCAD drastically reduced the time required to produce high-quality insoles. What once took 30 minutes per insole now takes just 5 minutes, thanks to the software's intuitive workflow and precision. This time-saving has significantly increased the company's production capacity, allowing it to meet high demand without additional labour.

Moreover, LutraCAD's focus on clinical validity ensures that each product meets the necessary medical standards. It gave ORTHODESIGNS the ability to produce both functional and aesthetically pleasing orthotic devices. The seamless integration of LutraCAD has led to a reduction in design errors, waste, and rework. This has further contributed to the overall efficiency and cost-effectiveness of their work.

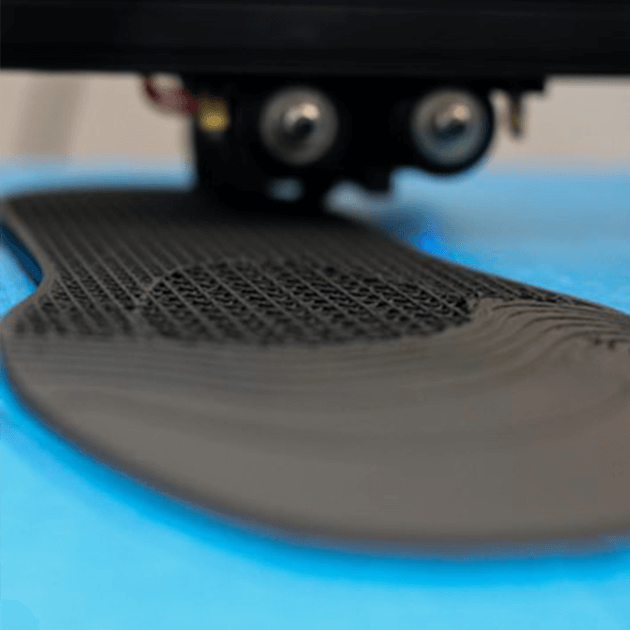

Insole printed

Insole printed

"Overall, I'm very satisfied with LutraCAD. The constant updates and new features demonstrate that LutraCAD is committed to improving their product, which helps us stay at the cutting edge of insole design."

Kyriakos Efstathiou - ORTHODESIGNS

Results and Benefits

Since adopting LutraCAD, ORTHODESIGNS has experienced several key benefits, such as keeping up with the growing demand without increasing labour costs. Due to more precision in their designs, they could reduce reworks and material waste, lowering their overall production costs. The designs have significantly enhanced consistency and quality, and the time to design the insoles has been reduced.

And their most important result, because by improving efficiency and design quality, ORTHODESIGNS has been able to meet their clients' needs more effectively.

Why ORTHODESIGNS chose LutraCAD

Several facts have influenced ORTHODESIGNS' decision to choose LutraCAD. Their most critical demand was a faster, more efficient workflow, and LutraCAD's software outpaced the company's previous methods, cutting design time by more than 80%.

Furthermore, ORTHODESIGNS wanted their products to be functional and visually appealing. LutraCAD's software allowed them to strike this balance without compromising speed.

What sealed the deal for them was the exceptional customer service provided by LutraCAD's team, which offered hands-on assistance throughout the integration and product development phases. This, together with the functionality, clinical accuracy, and aesthetic control, made LutraCAD the perfect fit for ORTHODESIGNS' needs.

"They have a quick and responsive customer service, which was a big plus for us. It ensures any issues or questions are resolved promptly, allowing us to maintain smooth operations."

Kyriakos Efstathiou - ORTHODESIGNS

Conclusion

By incorporating LutraCAD's software into their workflow, ORTHODESIGNS has overcome the challenges posed by their previous manual design process. The significant time savings, improved product consistency, and cost efficiency have helped the company scale its operations while maintaining high standards of quality and customer satisfaction while cutting costs through reduced reworks.

ORTHODESIGNS is positioned perfectly well for their future growth, and LutraCAD is happy with its contribution.

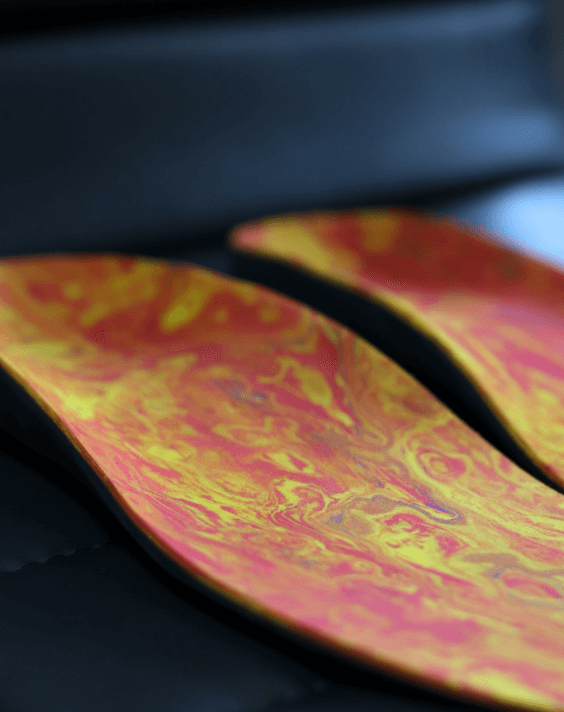

Insole printed with topcover

Insole printed with topcover

More info?

At LutraCAD, we are not only specialized in insole, shoe last, and midsole design, but we also have expertise in any scanning and production technique. If you need assistance with any projects related to these areas, please don't hesitate to reach out to us.